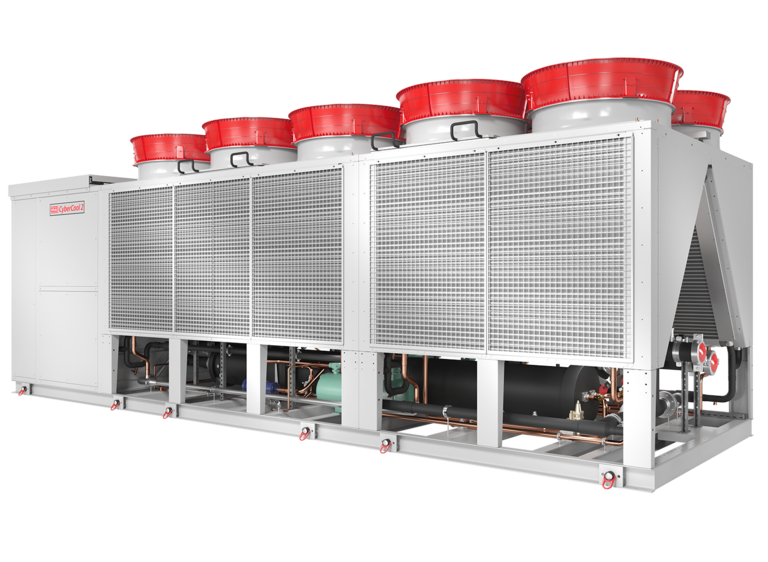

Databarn is a company that offers various different customers space to house its servers. They are purring in the server room on the first floor and ground floor and thereby produce a lot of heat. Without cooling it could easily reach sixty degrees Celsius. A row of dozens of condensers on the circulation of the first floor prevents this. The disadvantage of this so-called DX cooling is that this system uses compressors in both summer and winter to cool the air in the computer rooms. “And the compressors are the main energy guzzlers of the system,” says Van Goor. “Our new Stulz CC2 installation does that very differently: with a separate energy-saving 'coil'. This ensures that if the outside temperature falls below a value, the server room is cooled with water that flows through it. ”

The CC2 installation already switches to a kind of energy-saving mode ("mixed cooling mode") when the outside temperature is a few degrees below that in the server room. In doing so, he partly uses free cooling. If the outside temperature drops further, the compressor cooling can switch off completely. With full cooling load at a temperature of 4 degrees Celsius, the compressors can even be switched off completely. The installation only runs on its large power consumers when it is warmer than about 21 degrees outside. Since this is only the case for a modest number of days of the year in the Netherlands - the average temperature in our country is 10.1 degrees Celsius - the potential profit is considerable. “In any case, dozens of percentages on an annual basis,” says Van Goor. "That is why the investment in the installation pays for itself within a few years."

To replace the existing twenty-year-old installation with the STULZ CC2 chiller, a few interventions are required at Databarn. First, a construction of steel trusses was mounted on the roof. It rests on the columns of the building. In addition, a new distributor has been built in with a primary and a secondary system. In the primary system, water goes back and forth between the chiller and the distributor via a return pipe. In the secondary system, a distribution pump, with the aid of a delta p controller, ensures that cooled water ends up in places where the temperature rises the most. The set-up with two separate systems makes it easy in the future to connect additional chillers if necessary. When the number of customers increases, Databarn can easily install a second installation on the roof.

Heat is disastrous for the sophisticated electronics in the servers, so cooling is essential for Databarn's business operations. In the server room, warm air that rises from the dozens of continuously running server units is extracted at the top and discharged to the computer rooms installed inside (air conditioning computer room). The installation on the roof has coils on the outside for free cooling. These are made of aluminum. Cooling water with glycol passes via micro channels through thin pipes with fins and is thus cooled by the outside air. A row of large fans on top of the installation provides the supply of air. The DX coils are located on the inside of the installation. The compressors connected to it use the refrigerant freon R410A. This part of the installation is switched on when the free cooling unit cannot bring the temperature of the water down sufficiently.

When the rooftop cooling process is complete, the cooled water returns to the server room through a piping system. A heat exchanger there cools the air that is passed along it. This is then blown back in via the raised computer floor. STULZ chose to carry out the transport of water via ABS plastic pipes. This prevents rust formation, among other things.