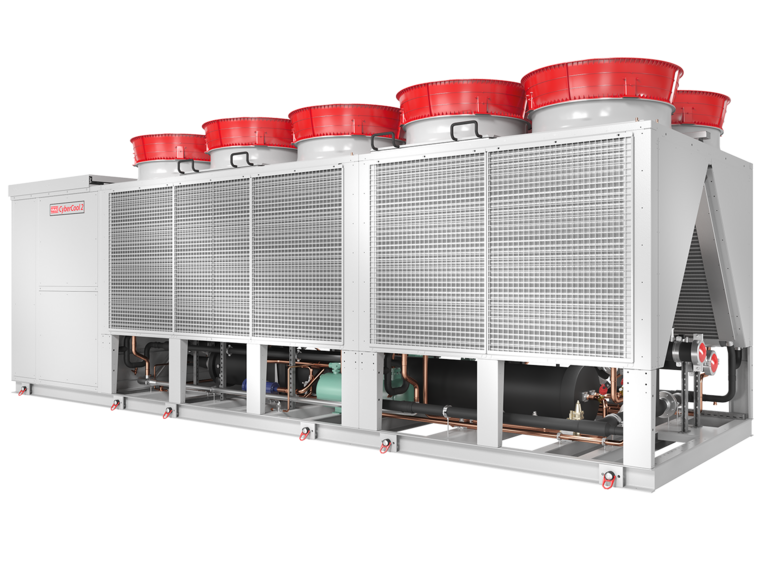

To meet the above stated requirements, a total of six CyberCool 2 chillers from STULZ, each with a cooling capacity of 1200 kW, were chosen to place on the roof of the data center. In the server rooms, it was decided to use one type of STULZ unit (the CyberAir 3) in order to increase efficiency. In the 400 kW server rooms, the STULZ CyberAir 3 units provide a cooling capacity of 200 kW per unit, in the 800 kW and 1000 kW server rooms they deliver less than 200 kW per unit, however, more units will be installed to meet the requirements. The CyberCool 2 chillers are all six equipped with the most energy-efficient components, including the option of Free Cooling mode. It is almost impossible to develop a more complete cooling unit.

The CyberCool 2 and the CyberAir 3 are the most energy efficient solutions in comparison

with competitive solutions on the market. This translates into a visibly lower energy consumption. The ROI is high and the units ultimately pay for themselves completely. The total cooling installation contains three water-separated cooling systems, one of which can fail completely (the installations consist of N + 1). This means that, for example in a 400 kW room, three STULZ CyberAir 3 units have been installed, each with a cooling capacity of 200 kW. This results in a total cooling capacity of 600 kW and each STULZ unit gets its cooling water from a different cooling system. If one STULZ unit should fail, the required cooling capacity will be realized by the other two STULZ units. The same situation has been realized on the roof of the data center. Two chillers are connected to each cooling system and if even two chillers fail (whichever one), the cooling is still guaranteed in the entire data center.

The unique factor in the project is the choice to place six custom-made (sea) containers on the roof of the data center. Various components are housed in these six containers, including the buffer tanks, but also the adiabatic cooling of CAREL (ChillBooster units). An advantage of adiabatic cooling is that the cooling capacity increases when the outside temperature rises, while this decreases with traditional compressor cooling. It cools the air before it reaches the chiller. For example, 100 litres of water supplies approximately 69 kW of cooling with only 0.25 kW of power absorbed by the pump. This ensures that energy consumption is reduced on the hottest days of the year. In addition, water as a refrigerant is completely environmentally friendly in contrast to traditional refrigerants.

Besides that, cost efficiency played a major role in the decision to place a part of the installation in six separate containers. In addition, a significant advantage was that the installations are better protected against, among other things, weather influences. By placing LED lighting in the containers, the service engineers can easily perform their work at any time of the day, including during the (dark) night hours. This cooling installation is also equipped with the option of transferring the heat produced in the server rooms to, for example, a heat network in the future.